Not All Wheel Hub Assemblies Are Created Equal

Not All Wheel Hub Assemblies Are Created Equal—Here’s What Sets PTC Apart

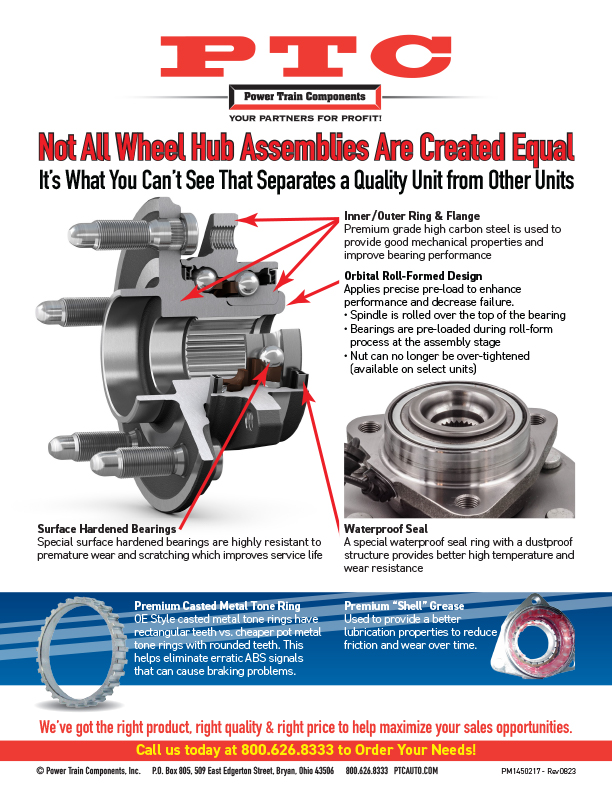

From the outside, most hub assemblies look the same—but it’s what’s inside that determines long-term performance and reliability. PTC hub assemblies are built to OE-level specs and beyond, using high-grade materials and precision manufacturing processes that eliminate premature failure and increase service life.

Key Features That Make PTC the Better Choice:

- Waterproof Seal – Special ring design with a dustproof structure resists heat and wear

- Surface-Hardened Bearings – Prevent premature wear and scoring for extended service life

- High Carbon Steel Inner/Outer Rings – Improve mechanical strength and performance under load

- Orbital Roll-Formed Design (on select units) – Applies precise preload and prevents over-torque damage

- OE-Style Casted Metal Tone Rings – Rectangular teeth for consistent ABS signal and braking control

- Premium Shell Grease – Reduces friction and wear for smoother operation over time

Why Orbital Roll-Forming Matters:

This process rolls the spindle over the bearing during assembly, creating a precise factory-set preload. Unlike units that require torquing, this eliminates the risk of over-tightening and bearing failure.

Don’t Settle for Visual Similarities

PTC hub assemblies may look like others on the shelf—but they perform in ways many competitors simply can’t match. Premium components inside every unit help ensure consistent, safe performance and longer life.